Table of Contents

TogglePipeline ruptures and major leaks are rare, but when they happen, the first minutes matter most. A line break valve is an emergency isolation valve (or a shut-off valve paired with dedicated trip logic) designed to automatically close when operating conditions suggest a line failure, such as a rapid pressure drop or abnormal flow behavior. The goal is simple: limit release volume, reduce downstream risk, and give operators control back faster.

Unlike standard isolation points that rely on manual action, this is a “detect-and-act” setup built for incidents you don’t have time to manage with phone calls and field travel.

What a line-break isolation valve is (and what it isn’t)

This type of automatic shutoff is most often applied as a fast isolation point on pipelines and critical segments where rapid closure is preferred or required by the project’s safety philosophy. To avoid confusion during procurement, separate the two functions early: emergency isolation closes the line to stop flow feeding a rupture, while pressure relief opens to vent or bypass pressure to protect equipment. Both matter, but they solve different problems, and specs get messy when teams treat them as interchangeable.

If you’re building an isolation program across multiple pipeline services, it helps to start from the GOWIN Industrial Valve homepage so your selections stay consistent with available body styles, pressure classes, and actuation options.

How a line-break shutdown function works

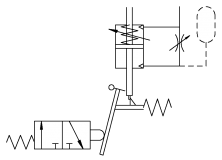

Most projects implement the same “safety chain” from detection to closure. What differs is the trip method, actuator package, and how you prevent nuisance trips.

1) Detection logic: pressure/flow “break signature”

A line-break shutdown function typically monitors one (or a combination) of these:

- Rate-of-pressure-drop (how fast pressure is falling)

- Differential pressure across a reference point

- Abnormal flow deviation (flow/pressure relationship outside expected operating envelope)

When the logic sees a pattern consistent with a major leak, it arms the shutdown command to the valve actuator.

2) Decision + interlocks to reduce nuisance trips

Pipelines see normal transients, start/stop events, compressor changes, and demand swings. A well-designed line break control valve package includes trip logic that filters noise without delaying real emergencies.

Common interlocks include:

- Short time confirmation (seconds) before trip

- Setpoint bands (warning threshold vs shutdown threshold)

- Arming conditions (only active above minimum pressure/flow)

- Optional sensor voting (when redundancy is required)

This is also where you’ll see the term line break control valve used in specifications; buyers are often describing the full safety function, not just a valve body.

3) Actuation, fail-safe position, and confirmation

Once a trip is declared, the actuator drives the valve to its safe position, typically fail-closed for natural gas and hazardous media. Your actuator choice should match site constraints and required closing time:

- Pneumatic actuation (fast, where instrument air is available)

- Electric actuation (simple utilities, needs correct torque/time sizing)

- Hydraulic / gas-over-oil packages (common for remote, large, high-torque valves)

For pipeline isolation applications, many teams shortlist valve bodies first (often ball valves), then finalize the actuator package to meet closing time and fail-safe requirements.

Where line-break isolation is used

Gas transmission and distribution segments

A line break valve in gas pipeline projects is typically positioned to isolate sections where rapid automatic shutoff reduces hazard and loss, especially across long corridors or remote stretches where manual isolation could take too long.

High-consequence and hard-to-access crossings

Automatic isolation is also considered for:

- River crossings and environmentally sensitive zones

- Long-buried segments with limited access

- Tie-ins around stations where an emergency shutdown system must act fast

Specification checklist for buyers

Procurement goes smoother when you define the duty clearly and keep the valve + actuator + logic as one package. Use this checklist to keep offers comparable.

1) Select the shut-off valve style

For emergency isolation, ball valves are common because they operate with a 90° turn and can deliver a strong shut-off when correctly specified.

To keep your product selection aligned with what’s available on your site, reference the Ball Valves category as your starting point, then shortlist an actuation method such as a Gas Over Oil Actuated Ball Valve for remote/high-torque pipeline duties, or a Motorized Ball Valve where electric actuation makes sense.

2) Define trip philosophy in writing

Put the trip method on the datasheet so everyone is aligned:

- Rate-of-drop threshold + time window

- Permissives/arming conditions

- Reset requirements (manual reset vs remote re-arm)

3) Confirm feedback, testing, and maintenance approach

A safety shutdown function is only trustworthy when it’s testable. Include:

- Open/close position feedback to confirm travel

- Periodic functional testing procedure (and responsibility)

- A clear reset workflow after a trip event

4) Don’t forget pressure protection

Isolation reduces release volume, but pressure protection protects equipment. If your line needs relief protection, reference the pressure relief valve page or the safety valve page as appropriate, then keep relief sizing and isolation logic as separate line items in your design review.

If your application needs throttling or a packaged regulating solution upstream/downstream of the shutdown point, the control valves page is also a helpful internal reference for buyers who need regulating duty, not just on/off isolation.

Recommended internal reads for pipeline shutoff programs

To help readers move from “definition” to “how to buy/spec,” these two internal articles fit naturally right after the specification checklist: How to Choose an ESD Ball Valve? and What is a PST Test for ESD Valves?

Conclusion

A line break valve strategy is ultimately about fast, reliable isolation when abnormal conditions suggest a rupture, so the pipeline stops feeding the event, and operators can regain control quickly. If you treat the valve, actuator, trip logic, and feedback as one integrated safety function, you’ll avoid mismatched packages, nuisance trips, and testability gaps that show up later at commissioning.

If you’re planning a new shutdown philosophy or upgrading an existing one, start from theGOWIN Industrial Valve homepage, then route requirements and drawings through Contact / Get a Quote so the selection (body, seats, actuator, and shutdown logic) matches your duty conditions.

3 Key Takeaways

- A line break valve can close automatically when conditions indicate a major leak/rupture, helping limit release volume.

- The “right” package includes valve + actuator + trip logic + feedback, not just a valve body.

- Isolation (shutdown) and pressure relief serve different roles; specify both clearly when needed.

FAQs

Q1: What is a line break valve used for?

A1: A line break valve is used to isolate a pipeline segment automatically during suspected rupture conditions, so upstream flow stops feeding the leak.

Q2: How does a line-break shutdown system detect a rupture?

A2: Most systems detect a “break signature” using rate-of-pressure-drop, differential pressure, and/or abnormal flow behavior, then trigger a shutdown command to the actuator.

Q3: What does a line relief valve do?

A3: A relief valve protects equipment by opening at a set pressure to discharge or bypass excess pressure. It does not isolate a rupture; it manages overpressure.

Q4: What are the three types of valves?

A4: A practical buyer-friendly grouping is isolation valves (on/off shut-off), control valves (regulating/throttling), and check valves (preventing backflow).Q5: What is the best shut-off valve for natural gas?

A5: For many gas isolation points, a correctly specified ball valve with the right seats, pressure class, and actuator sizing is a common choice, especially where fast closing and dependable shutoff are required.