Table of Contents

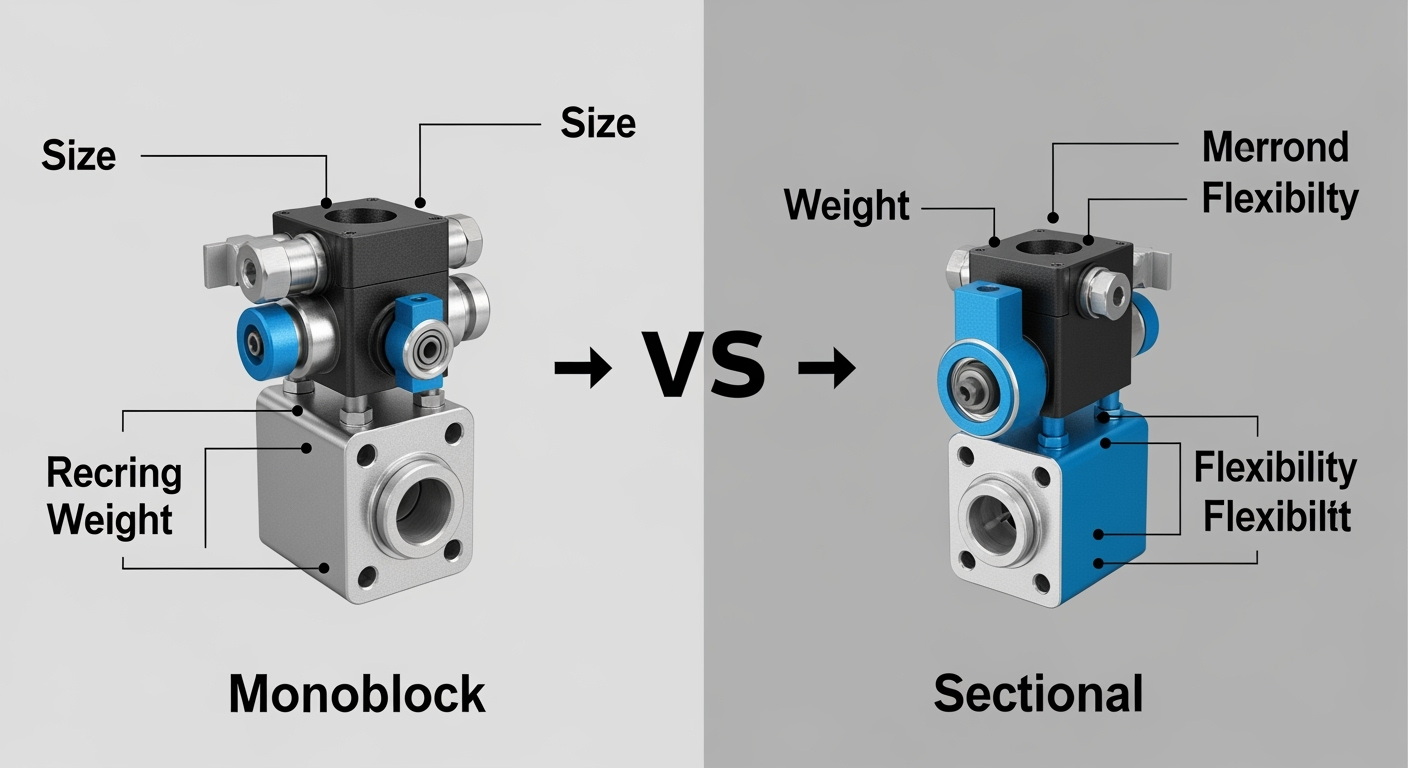

ToggleMonoblock vs. Sectional Hydraulic Valves: A Head-to-Head Comparison

Choosing the right hydraulic control valve is essential for system efficiency, reliability, and cost-effectiveness. The two common hydraulic control valve types are monoblock and sectional valves. Each has unique benefits, limitations, and applications. Understanding the differences helps buyers and engineers select the right solution for their equipment.

GOWIN Industrial Valve provides high-quality monoblock hydraulic control valves and sectional hydraulic control valves. With strong customization capabilities, GOWIN can manufacture valves based on customer drawings or specific needs, ensuring on-time delivery and reliable technical support worldwide.

What is a Monoblock Control Valve?

A monoblock hydraulic control valve is a single-piece casting with multiple spools built into one body. It is compact, cost-effective, and easy to install. These valves are commonly used in systems with fixed functions and lower to medium flow and pressure requirements.

Pros:

- Lightweight and compact design, which saves space in mobile machinery such as loaders and sprayers.

- Fewer leak points due to the one-piece casting, lowering the risk of hydraulic fluid loss.

- Generally more affordable than sectional hydraulic control valves, making them attractive for cost-sensitive projects.

- Easier to install because of their single-body structure, reducing assembly time for OEMs.

Cons:

- Limited flexibility; the number of spools or sections cannot be modified after manufacturing.

- If a spool or internal part fails, the entire monoblock hydraulic control valve often requires replacement.

- Typically designed for lower flow rates and pressures, so they may not be suitable for heavy-duty industrial systems that require high-capacity hydraulic control valve types.

GOWIN manufactures monoblock hydraulic control valves suitable for industries like mining, steel production, and water treatment. Custom designs are available to meet unique application requirements.

What is a Sectional Control Valve?

Sectional hydraulic control valves are built using separate sections bolted together. Each section controls one function, allowing flexibility in system design. These valves are ideal for complex machinery with varying functions and high flow or pressure demands.

Pros:

- Highly flexible; sections can be added or removed to suit different functions, making them ideal for complex hydraulic control valve types used in mining, steel plants, and water treatment systems.

- Easier and cheaper to service because only the faulty section is replaced, which reduces downtime and maintenance cost.

- Can handle higher operating pressures and flow rates, supporting heavy-duty applications that require robust sectional hydraulic control valves.

Cons:

- More potential leak points due to multiple bolted connections, requiring correct torqueing during assembly.

- Heavier and bulkier compared to a monoblock hydraulic control valve, which may affect installation in space-limited systems.

- Slightly more expensive upfront, but long-term savings may offset this due to flexibility and easier repairs.

GOWIN’s sectional valves are built for industrial systems requiring versatility. They can be produced according to customer specifications, ensuring compatibility with different hydraulic control valve schematics.

High-performance control valves engineered to international standards (ASME, API, JIS, BS, DIN). Available in sizes from 3/4″ to 72″ with pressure ratings up to 42.0 MPa. Suitable for water, oil, and gas applications with temperature range from -196℃ to 650℃.

Explore ProductKey Decision Factors: Flow Rate, Pressure, and Application

When comparing types of hydraulic control valves, consider the system’s flow rate, operating pressure, and space constraints. For fixed, cost-sensitive applications, a monoblock hydraulic control valve is often the best choice. For complex machines needing multiple functions or future modifications, sectional hydraulic control valves are ideal.

Flexibility and Repairability: Why Sectional Valves Shine

Sectional valves provide unmatched flexibility. Technicians can add sections for new functions or remove them to simplify the system. Servicing is easier since only the faulty part needs replacement, reducing downtime and maintenance costs.

Cost and Compactness: The Case for Monoblock Valves

Monoblock valves are compact and budget-friendly. They reduce installation time and are less prone to leaks because of their single-piece design. For mobile machinery, agricultural equipment, or smaller hydraulic systems, they offer a practical solution.

Application Spotlight: Mobile Machinery vs. Complex Industrial Systems

- Monoblock valves are widely used in loaders, agricultural sprayers, and smaller construction equipment. Their compact design and lower cost make them perfect for mobile systems.

- Sectional valves are preferred in industrial machinery, mining equipment, and systems requiring high-pressure and high-flow capabilities.

GOWIN ensures that both valve types meet strict quality standards and are delivered on schedule. Their international support team helps distributors and OEMs with fast technical assistance and problem resolution.

FAQs

What is a monoblock hydraulic control valve?

It is a single-piece valve with multiple spools. It is compact, affordable, and has fewer leak points but is less flexible.

What is a sectional hydraulic control valve?

It is made of separate sections bolted together, offering flexibility and easier repairs. It is ideal for complex systems.

Which valve is better for high pressure?

Sectional valves are better for high-pressure and high-flow applications.

Can GOWIN customize valves?

Yes. GOWIN can produce valves based on customer drawings and special needs.

Does GOWIN provide technical support?

Yes. GOWIN’s global service team provides fast technical support and problem-solving.

Conclusion: Making the Right Choice for Your Customers

Both monoblock hydraulic control valves and sectional hydraulic control valves have their place in industrial applications. The right choice depends on cost, system complexity, and performance needs. GOWIN offers both valve types with customization options, ensuring that agents and distributors can meet diverse customer requirements while maintaining a reliable supply chain.Contact GOWIN today to request a quote or speak with our technical experts about the best hydraulic control valve types for your system.