Table of Contents

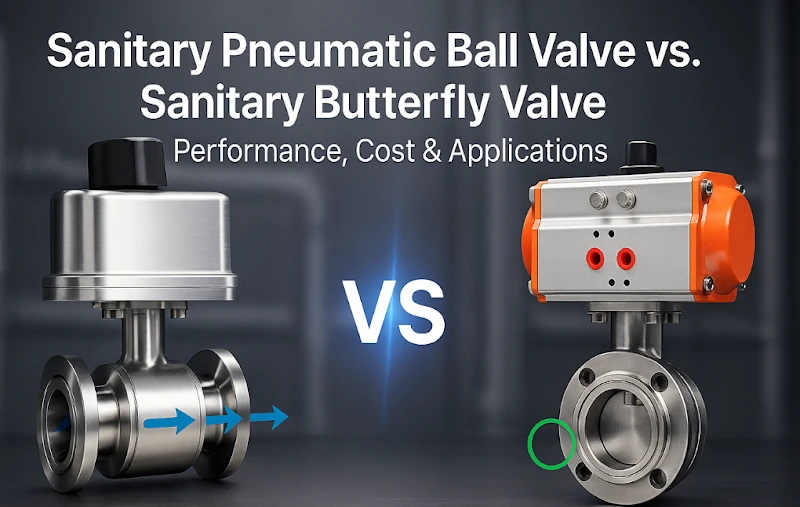

ToggleSanitary pneumatic ball valves excel in high-pressure applications and provide superior sealing for critical process isolation. Sanitary butterfly valves offer significant cost savings and compact design for large-diameter, low-pressure utility systems where space and budget constraints are primary concerns.

What Is A Sanitary Pneumatic Ball Valve?

A sanitary pneumatic ball valve uses a spherical ball with a cylindrical port that rotates 90 degrees to control flow. When the port aligns with the pipeline, fluid flows freely. A quarter turn blocks flow completely.

The pneumatic actuator provides precise control through compressed air. This design maintains sterile conditions critical for food processing, pharmaceuticals, and biotechnology applications. Sanitary ball valves feature polished surfaces, cavity-filled designs, and FDA-approved materials.

What Is A Sanitary Butterfly Valve?

A sanitary butterfly valve with pneumatic actuator uses a rotating disc that pivots on a central shaft to control flow. The disc moves from fully open to completely closed with a 90-degree rotation.

The pneumatic actuator design provides automated control while maintaining hygienic requirements. The butterfly disc stays in the flow stream even when fully open, creating some restriction but offering a compact design and lighter weight.

Now let’s compare how these different designs affect performance, cost, and applications.

Performance Comparison

| Feature | Sanitary Ball Valve | Sanitary Butterfly Valve |

| Pressure Rating | Up to 1000+ PSI | Up to 150 PSI typical |

| Flow Path | Full-bore, unobstructed | Slight restriction from disc |

| Sealing | Excellent bubble-tight shutoff | Good sealing, pressure-dependent |

| Size/Weight | Larger, heavier construction | Compact, lightweight design |

Pressure Handling

Sanitary ball valve vs butterfly valve pressure ratings show major differences. Ball valves handle substantially higher pressures due to their robust construction and sealing mechanism. The spherical design distributes pressure evenly.

Butterfly valves work best in low to medium-pressure applications. The disc and seat arrangement becomes less effective as pressure increases, limiting their use in high-pressure sanitary systems.

Flow Characteristics

Ball valves provide unobstructed flow when fully open, making them ideal for flow control valves applications requiring minimal pressure drop. This benefits viscous fluid handling and supports pipeline cleaning operations.

Butterfly valves create permanent flow restriction and turbulence even when fully open. This affects pumping energy and may impact product quality in sensitive applications.

Cost Comparison

| Cost Factor | Sanitary Ball Valve | Sanitary Butterfly Valve |

| Initial Purchase | Higher cost | Lower cost |

| Installation | More complex, heavier | Simple, lightweight |

| Maintenance | Less frequent | Periodic seal replacement |

| Energy Usage | Lower pumping costs | Higher due to flow restriction |

| Lifespan | Longer service life | Shorter, more replacements |

Upfront Investment

Butterfly valves cost less initially, especially for larger sizes. The simpler construction and reduced materials translate to significant savings for budget-conscious projects.

Ball valves require higher initial investment due to complex machining and robust construction. However, this often pays off through extended service life and reduced maintenance.

Long-Term Costs

Ball valves typically need less frequent maintenance due to robust design and superior sealing. The disc and actuator mechanisms in butterfly valves require regular inspection and seal replacement.

Energy costs favor ball valves in continuous flow applications due to their unobstructed flow path. Butterfly valves consume more pumping energy due to permanent flow restriction.

Application Selection Guide

| Application Type | Recommended Valve | Key Considerations |

| High-pressure systems (>200 PSI) | Ball Valve | Pressure rating and actuator torque requirements |

| Large diameter, low-pressure | Butterfly Valve | Cost advantages and space constraints |

| Viscous fluids (>100 cP) | Ball Valve | Full-bore design prevents clogging, higher Cv |

| Tank bottom outlets | Ball Valve | Bubble-tight sealing and drainability required |

| CIP circuits | Both acceptable | Design-dependent: cavity-filled vs proper clearances |

| SIP sterilization | Material dependent | PTFE seats for ball valves, silicone for butterfly |

| Shear-sensitive products | Ball Valve | Minimal turbulence and flow restriction |

Industry Applications

Valve selection for food industry facilities requires balancing performance, cost, and hygienic requirements. Different food processing applications have varying priorities based on their specific operational demands.

Food And Beverage Processing

Ball valves suit critical applications where absolute sealing is essential. Butterfly valves work well for utility systems and low-pressure process lines. Both types support CIP operations, but ball valves provide advantages through unobstructed flow paths.

Pharmaceutical Manufacturing

These industries typically favor ball valves for superior sealing and validation-friendly design. The ability to achieve bubble-tight shutoff supports process validation and regulatory compliance.

Dairy Processing

Ball valves perform well in high-pressure homogenization systems and tank bottom outlets in dairy applications. For utility systems requiring automated control, the choice between electric and pneumatic actuators depends on available utilities and response time requirements.

Making Your Selection

When choosing between valve types, consider these key factors:

Choose ball valves when:

- High pressure requirements exceed 200 PSI

- Bubble-tight sealing is critical for product quality

- Handling viscous fluids that require minimal pressure drop

- Long-term reliability justifies higher initial cost

- On/off isolation service is the primary requirement

Choose butterfly valves when:

- Working with large diameters where cost savings matter

- Low to medium pressure applications under 200 PSI

- Space constraints favor compact designs

- Initial budget limitations are the primary concern

- On/off service without precise throttling requirements

Note: Both valve types are designed primarily for on/off service. Neither provides precise throttling control suitable for modulating applications without special modifications.

Conclusion

Sanitary ball valve vs butterfly valve selection depends on balancing performance requirements against cost constraints and installation considerations. Ball valves provide superior performance and longevity in demanding applications, while butterfly valves offer cost-effective solutions for less critical systems.

At GOWIN Industrial Valve, engineers help specify appropriate sanitary valve configurations based on actual process requirements and long-term operational goals. Understanding these differences ensures optimal valve selection for food processing, pharmaceutical, and biotechnology applications.View our complete range of pneumatic ball valves, or learn more about pneumatic actuator options for automated valve control systems.