Table of Contents

ToggleAutomation rarely fails because “the valve is bad.” It fails because the valve, actuator, power supply, and controls were never specified as one system. A motor-driven quarter-turn valve closes that gap by pairing a ball valve with an electric actuator, so you can command open/close from a controller without sending an operator to the line.

Explore the full range on the GOWIN Industrial Valve. If you’re evaluating automated isolation, diverting duties, or remote shutoff, this guide explains where electric actuation fits best and how to avoid selection mistakes.

What an electric-actuated ball valve actually does

An electric actuator converts electrical power into torque and rotates the ball 90° to align (open) or block (close) the flow path. In most industrial setups, this is about repeatable on/off isolation, not precision throttling.

It’s best suited for remote isolation in hard-to-reach or hazardous areas, automated shutoff based on a PLC, BMS, or sensor signal, larger line sizes where solenoid valves become impractical, and dirtier media or mixed-quality fluids where small pilot passages could clog.

It’s not designed for ultra-fast “instant” switching (solenoids are typically faster) or high-precision throttling if modulation is critical, specify a dedicated control valve or a V-port trim. Internal read: If you want to separate responsibilities in an automated loop, see GOWIN’s article on the difference between valves and actuators.

Where motor-driven quarter-turn valves are used in industry

Most buyers choose electric actuation for one reason: controlling valves at scale without adding manual labor or safety exposure. Common use cases include:

Water and wastewater automation

In water and wastewater systems, motorized actuation is commonly used on pump skids for automatic isolation, bypass control, and backwash routing. It’s also specified for chemical dosing isolation as a secondary shutoff, and for remote valve banks that automate switching between treatment stages.

HVAC, utilities, and building services

In HVAC and utility piping, electric actuation is often applied on hot and chilled water loops for remote isolation, on energy metering branches and maintenance bypasses, and on automated make-up water and tank fill lines where operators need dependable on/off control without manual intervention.

Oil, gas, and general process service

Where process conditions require a robust quarter-turn body, buyers often specify electric actuation for:

- Remote block valves on manifolds

- Tank farm transfer lines and loading bays

- Utility oil, gas, and water services (within the valve’s material and temperature limits)

Related product: Side Entry Trunnion Ball Valve

Hero Product Highlight

- Product: Motorized Ball Valve

- Nominal diameter: 1/2″–56″ (DN15–DN1400)

- Pressure: 150LB–2500LB (2.5–42.0 MPa)

- End connections: RF, RTJ, BW, THR, SW

- Temperature: -196°C to 650°C

For full specifications and options, browse GOWIN’s ball valves.

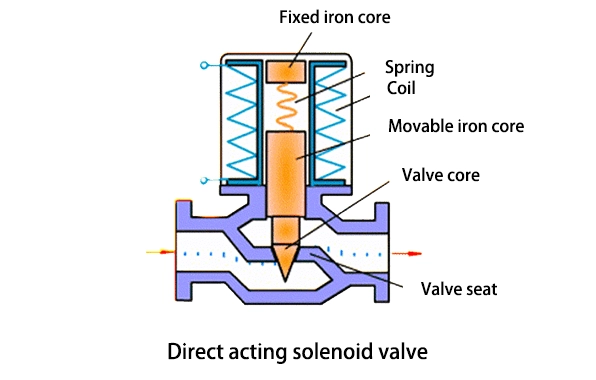

Electric actuator vs. solenoid valves: when to pick which

Solenoid valves and motor-driven quarter-turn valves can both automate flow, but they solve different problems.

Choose a motor-driven quarter-turn when you need:

- Higher flow/pressure capability and larger sizes

- More tolerance to debris or dirty media

- Lower holding power draw (many designs draw power mainly during movement)

Choose a solenoid when you need:

- Very fast response time

- Small ports, low flow, or pilot-controlled circuits

- Simple “on/off” control in compact manifolds

2 way vs. 3 way motorized configurations

Actuation is only half the story; porting determines the function.

2 way shutoff (straight-through)

A “2 motorized ball valve” is your standard open/close isolation valve. It’s typically used for line shutoff, automated bypass open/close, and safety shutoff applications where the control system commands a closed state.

3 way diverting or mixing

A 3-way body can route flow between two outlets (diverting) or blend from two inlets (mixing), depending on the internal bore and piping layout. A “3 way motorized ball valve” is often selected for switching between duty/standby equipment, diverting flow to a drain, recirculation line, or alternate treatment stage, and basic mixing in low-to-moderate accuracy services. If your piping drawings call it out as “Motorized ball valve 3 way,” confirm whether it’s an L-port or T-port configuration and what the default (fail) position should be.

Fail-safe orientation: normally open vs. normally closed

A normally open motorized ball valve is chosen when your process must keep flowing on power loss (for example, to prevent overheating or to maintain minimum circulation). For “fail-closed” safety logic, specify normally closed instead. Always define the fail position in the datasheet and confirm it matches your control philosophy.

Buyer checklist: specs that make or break reliability

Before you sign off on an actuated package, confirm these basics with your valve supplier:

| Spec to confirm | Why it matters |

| Media | Clean water, hydrocarbons, corrosives, or slurry will determine body/trim materials and sealing approach. |

| Pressure & temperature | Include startup and upset conditions, not just normal operating values. |

| Seat type | Soft seats prioritize tight shutoff; metal seats improve durability in abrasive or higher-temperature service. |

| Porting | Full bore vs. reduced bore affects pressure drop and flow/Cv expectations. |

| Actuator torque | Confirm breakaway torque and keep a safety margin for worst-case conditions. |

| Power & control | AC/DC voltage, wiring method, and whether you need feedback/position indication. |

| Environmental rating | Indoor/outdoor exposure, washdown needs, and any hazardous-area requirements. |

Internal read: For actuator selection fundamentals, start with GOWIN’s guide to choosing a valve actuator.

Installation & maintenance notes that save downtime

Actuated valves are most dependable when the installation supports them. In practice, that means keeping wiring accessible and labeling terminals clearly, adding upstream strainers where debris is expected, especially on older pipework, and verifying the stroke/rotation and end stops during commissioning.

Conclusion

A motorized ball valve is used for one core job: reliable, repeatable isolation (and in some cases diversion) that you can control remotely. When you match porting, materials, actuator torque, and fail position to your real operating conditions, you reduce nuisance trips, prevent leaks, and keep maintenance predictable.

If you’re building a new skid, retrofitting manual valves, or standardizing spares, review the specifications on GOWIN’s automation-ready ball valve page and share your datasheet with the team via the Contact/Get a Quote page.

3 Key Takeaways

- Electric actuation is ideal for remote, repeatable on/off isolation in real industrial lines.

- Choose body/seat materials and actuator torque for worst-case conditions, not “normal” ones.

- Define porting and fail position early to avoid expensive piping and controls rework.

FAQs (People also asked)

Q1: What’s the difference between an electric actuated ball valve and a solenoid valve?

A1: Solenoids are typically faster for small on/off control, while motor-driven quarter-turn valves usually scale better for higher flows, larger sizes, and dirtier media.

Q2: How does an electric-actuated ball valve work?

A2: A control signal powers the actuator, which applies torque to the stem and rotates the ball 90° to open or close the flow path.

Q3: Can an electric actuated ball valve be used for throttling?

A3: It can “throttle” in a pinch, but standard quarter-turn valves aren’t built for precise control. If modulation matters, specify a V-port trim or a dedicated control valve.

Q4: What does “normally open” mean for an actuated valve?

A4: It describes the fail position. “Normally open” means the valve is designed to return to the open position on loss of power (depending on actuator type and design), keeping flow available.

Q5: What should I specify on a purchase order for an actuated ball valve?

A5: At minimum: valve size, pressure class, material, seat type, end connection, voltage, control signal, feedback needs, and the required fail position.