Table of Contents

ToggleA fuel changeover point may look like a small piece of hardware, but it carries a big responsibility onboard: keep engines consistently fed, prevent accidental tank-to-tank crossflow, and give crews a fast, predictable way to switch fuels when operating conditions change.

On many vessels, that responsibility sits with a marine fuel selector valve supported by isolation shutoffs, strainers, fittings, and clear position marking so the changeover is repeatable under real operating pressure.

Shipboard flow control components operate in tight machinery spaces with vibration, heat, and salt-laden air. That’s why the selector setup has to be reliable, serviceable, and clearly documented, not just installed and forgotten.

What a selector valve does (in plain terms)

- Routes fuel from one tank (or manifold) to an engine, day tank, or transfer line so operators can switch tanks or fuel grades without guesswork.

- Sits in a safety-critical circuit, so this marine valve should provide repeatable switching positions and a tight shutoff to reduce tank migration risk.

- Uses corrosion-resistant construction suitable for humid engine rooms and salt-laden environments.

- Allows practical service access for seals/packing during planned maintenance.

Where it fits in the fuel loop (and why that matters)

Most selectors sit after the tank outlet shutoffs and before the primary filtration and the engine lift pump. This arrangement keeps switching simple while reducing dead legs where sludge can settle.

A shipyard-friendly lineup typically starts with tank outlet shutoff valves, then a strainer for debris control, followed by the selector (clearly labeled), and finally fine filtration before the engine.

If you need filtration support upstream, many vessel fuel systems include a Marine Y valve (Y-type strainer), such as GOWIN’s Y Type Strainer.

Common selector designs onboard

1) Two-way selector (Tank A / Tank B)

This is the simplest changeover configuration and is often used for smaller craft, generators, or straightforward day-tank setups.

It works best when you only need to choose one supply source at a time, and you don’t need paired return switching.

2) Three-way selector (A / B / OFF or transfer mode)

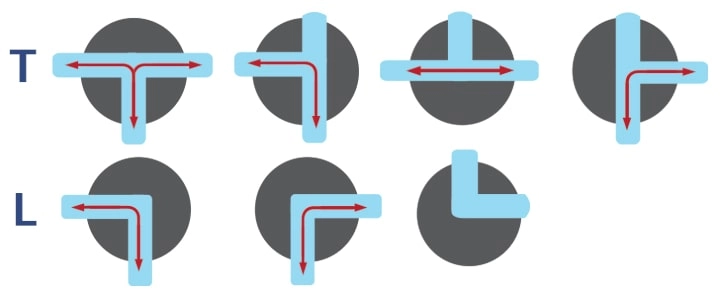

Many selectors are implemented using multi-port designs, and a 3-way body can add an OFF position for maintenance. However, it only works as intended if the internal porting matches your flow logic (for example, L-port vs T-port).

This is also where spec mistakes happen most often, because the handle position can look “right” while the internal flow path is wrong. If you’re standardizing on a familiar platform, a Marine ball valve range can be a good starting point, then confirm available 3-way configurations and porting options inside GOWIN’s Ball Valves.

3) Six-port selector (supply + return switched together)

On return-type diesel systems, a 6-port design switches both supply and return circuits together.

This helps prevent pulling from Tank A while returning to Tank B, which can cause cross-contamination and confusing tank level behavior.

If your system includes returns, confirm whether you need paired switching before selecting a body style. This one decision prevents a lot of troubleshooting later.

Specs that matter most for buyers

Materials & corrosion resistance

Salt air and bilge humidity can quickly degrade packing and external surfaces.

Many marine systems therefore use copper/bronze alloys or stainless steel, depending on the circuit, class requirements, and budget.

GOWIN’s material overview (copper, stainless steel, carbon steel, cast iron, and bronze) is a helpful starting point. For more guidance, you can review the related internal articleUnderstanding 5 Different Valve Materials, and if you need corrosion-resistant catalogs to shortlist from, see GOWIN’s Copper Valves.

Porting logic, indication, and lockout

Don’t accept “3-way” without a diagram. Require:

- porting diagram (flow path by handle position)

- positive stops/detents

- handle indicator that matches internal porting

- lockout provisions if your SOP needs them

Classification society and certification checkpoints

For classed vessels and offshore projects, it’s recommended to align specs with common classification society expectations. Depending on the scope, buyers may reference standards or approvals associated with ABS, DNV, and LR (and sometimes BV, CCS, or RINA).

In practical terms, this means confirming documentation requirements such as material traceability, test reports, and inspection records. It also helps you avoid late-stage procurement surprises during survey or acceptance.

Installation & maintenance basics

Even the best marine valve will fail early if it’s installed like generic plumbing. Treat the selector and every supporting isolation point as part of one assembly and design it for access and service.

Keep it reachable, support piping to reduce vibration loads, assemble clean to protect seats and seals, and label positions permanently. For a maintenance rhythm, GOWIN’s checklist is a solid baseline. See How To Maintain A Pneumatic Ball Valve.

Common mistakes (and how to avoid them)

- Most issues come from predictable causes: wrong internal porting, ignoring return-line behavior, poor access, or material mismatch.

- Documentation gaps create delays because crews and inspectors lose time verifying flow paths and switching positions.

- Build the specification around real operating behavior, not just valve size and end connection.

- Use a clear porting diagram and a permanent labeling plan to save hours during commissioning.

Conclusion

A fuel selector assembly is a control point you may need to operate under pressure, sometimes literally, so it’s worth getting the details right. Specify porting clearly, match materials to the operating environment, and design the surrounding piping so crews can switch safely and service the assembly without tearing down the system.

If you’re planning a newbuild, retrofit, or spares program, you can submit your requirements and request pricing through GOWIN’s Contact / Get a Quote page. This keeps sourcing aligned with the product range and documentation your project may require.

Key Takeaways

- Verify porting and indication so handle position matches the internal flow path.

- If the system has a return line, consider paired switching to reduce cross-tank mixing.

- For classed projects, confirm documentation and certification expectations early.

FAQs (People also ask)

What is a fuel selector valve used for on a boat?

It routes fuel from a chosen tank or manifold to the engine, generator, day tank, or transfer circuit. This allows safe switching between sources during normal operations.

Can I switch fuel tanks while the engine is running?

In many systems, yes, but follow a defined SOP. Confirm the receiving tank level, switch smoothly, and monitor pressure/vacuum.

What’s the difference between a 2-way and 3-way selector?

A 2-way switch switches between two sources. A 3-way may add an OFF position or alternate routing, depending on porting.

Why do some vessels use a 6-port selector?

Return-type diesel systems can pull from one tank and return to another if not designed carefully. A 6-port selector switches the supply and return together to reduce cross-contamination.

How do I choose the right Fuel selector valve marine configuration?

Start with system layout (supply only vs supply + return) and confirm porting behavior by diagram. Then, validate material, pressure/temperature, end connections, and documentation requirements.