विषयसूची

टॉगलA resilient wedge gate valve is a type of industrial valve designed to stop or allow the flow of water and other fluids with a tight, leak-free seal. It uses a rubber-coated wedge instead of a solid metal disc, making it more flexible, corrosion-resistant, and reliable in both directions of flow.

These valves are common in water distribution systems, wastewater plants, and fire protection pipelines.

In this guide, you’ll learn what a resilient wedge gate valve is, how it works, its benefits, and how it differs from other gate valve types, especially the metal-seated gate valve. Whether you’re new to valve systems or simply looking to understand their value, this article breaks it all down clearly.

Understanding the Resilient Wedge Gate Valve Definition

The resilient wedge gate valve definition refers to a valve that uses a rubber-encapsulated wedge as its closing element. When the valve is closed, the rubber wedge presses tightly against the ductile iron body, creating a bubble-tight shutoff. This design minimizes friction, reduces wear, and eliminates the jamming issues found in older metal designs.

The resilient seated wedge gate valve is built to meet standards like AWWA C515 and AWWA C509, ensuring durability, consistent performance, and long-term service in both underground and above-ground applications.

In simpler terms, this valve is engineered for strength, flexibility, and low maintenance, making it a top choice for modern fluid control systems.

How a Resilient Wedge Gate Valve Works

When the valve handle or गति देनेवाला is turned, the resilient wedge moves vertically inside the valve body. As it lowers, it seals against the body seats using its flexible rubber coating. The elastic properties of the rubber allow it to compress slightly, ensuring a perfect seal even if small debris or irregularities are present.

When opened, the wedge rises completely out of the flow path, allowing unrestricted water flow with minimal pressure loss. This makes the design ideal for on/off control rather than throttling.

Key components include:

- Body and bonnet: Typically made from ductile iron for strength.

- Wedge: Rubber-coated for corrosion resistance and flexibility.

- तना: Often made from stainless steel or bronze.

- Sealing: Fully encapsulated rubber meets ASTM D429 requirements.

Advantages of Using a Resilient Seated Wedge Gate Valve

- Leak-Free Performance: The rubber wedge provides a bubble-tight seal that prevents leakage even under high pressure.

- Low Operating Torque: It requires minimal effort to open or close—ideal for manual or motorized operation.

- Corrosion and Wear Resistance: The rubber coating protects internal surfaces from rust and mineral buildup, extending lifespan.

- Bi-Directional Shutoff: Unlike metal-seated types, the valve seals effectively in both flow directions.

- Reduced Maintenance: The design minimizes wear on sealing surfaces, lowering downtime and replacement costs.

These benefits make the series 2500 resilient wedge gate valve and similar models suitable for a wide range of industries, from municipal water systems to fire protection and industrial process control.

Applications of Resilient Wedge Gate Valves

The resilient wedge gate valves are versatile and widely used wherever water flow needs to be controlled reliably. Common applications include:

- Water and wastewater treatment plants

- Fire protection and hydrant systems

- Municipal water supply networks

- Industrial and power plant piping systems

- Irrigation and agricultural water control

These valves are also popular in underground installations, as they can handle harsh environments without frequent maintenance.

AWWA Resilient Wedge Gate Valve Standards

Every AWWA resilient wedge gate valve is built and tested under strict industry standards to ensure safety, reliability, and long service life. These standards prove that each valve can handle high pressure, resist corrosion, and perform smoothly in tough conditions.

Main certifications include:

- AWWA C515 / C509: Defines the design and performance requirements for ductile iron resilient wedge gate valves, including wall thickness, pressure rating, and durability.

- UL 262 / FM Approved: Confirms the valve meets fire safety and performance standards for critical water systems.

- NSF 61 / ANSI C550: Ensures coating quality and verifies that materials are safe for drinking water applications.

These AWWA resilient wedge gate valves undergo rigorous testing for coating adhesion, wall thickness, and pressure performance. Each resilient seated wedge gate valve is engineered to deliver reliable flow control and long service life in drinking water systems, wastewater treatment, and industrial applications.

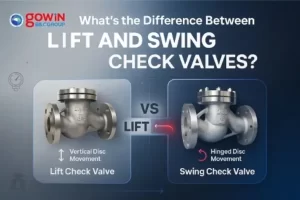

What Is the Difference Between Metal Seated and Resilient Seated Gate Valves?

The difference between metal-seated and resilient-seated gate valves lies in their sealing method.

- Metal-seated valves use metal-to-metal contact, which can wear down faster and require more torque to operate.

- Resilient-seated valves, on the other hand, use a rubber wedge that flexes to ensure a perfect seal, even with minor debris or surface imperfections.

In short, resilient types are quieter, easier to operate, and more suitable for water service, while metal-seated versions are often reserved for high-temperature or abrasive applications.

Why Choose GOWIN Industrial Valve

पर गोविन औद्योगिक वाल्व, every resilient wedge gate valve is crafted with precision and backed by एपीआई6डी, ISO9001, and OHSAS45001 certifications.

Our valves are manufactured using advanced testing facilities under ISO17025-accredited laboratories, ensuring unmatched quality and safety. With 16+ years of expertise, GOWIN provides customized valve solutions for water supply, chemical, and power generation industries.

When you invest in a GOWIN valve, you get:

- Long service life backed by global standards

- Precision manufacturing and strict testing

- Dedicated support from a professional engineering team

Conclusion: Smart Flow Starts with the Right Valve

A resilient wedge gate valve is a long-term investment in efficiency, safety, and reliability. Its flexible rubber design ensures a tight seal, low maintenance, and superior performance in both municipal and industrial applications.

If you’re looking for proven, certified solutions, explore our collection of resilient wedge गेट वाल्व at GOWIN Industrial Valve. We’re dedicated to helping you achieve safe, smooth, and reliable fluid control—no compromises.

अक्सर पूछे जाने वाले प्रश्नों

1. What is a resilient wedge gate valve?

A valve that uses a rubber-coated wedge to create a tight, leak-proof seal for controlling fluid flow in pipelines.

2. What are the advantages of resilient seated gate valves?

They offer leak-free sealing, low torque operation, corrosion resistance, and long service life.

3. Where are resilient wedge gate valves used?

In water supply, wastewater treatment, fire protection, and industrial piping systems.

4. What is the difference between metal-seated and resilient-seated gate valves?

Metal-seated valves use metal-to-metal contact; resilient-seated ones use rubber for a flexible, bubble-tight seal.

5. What standards do AWWA resilient wedge gate valves follow?

They follow AWWA C515/C509, UL262, FM, and NSF 61 for performance and safety.