Tabla de contenido

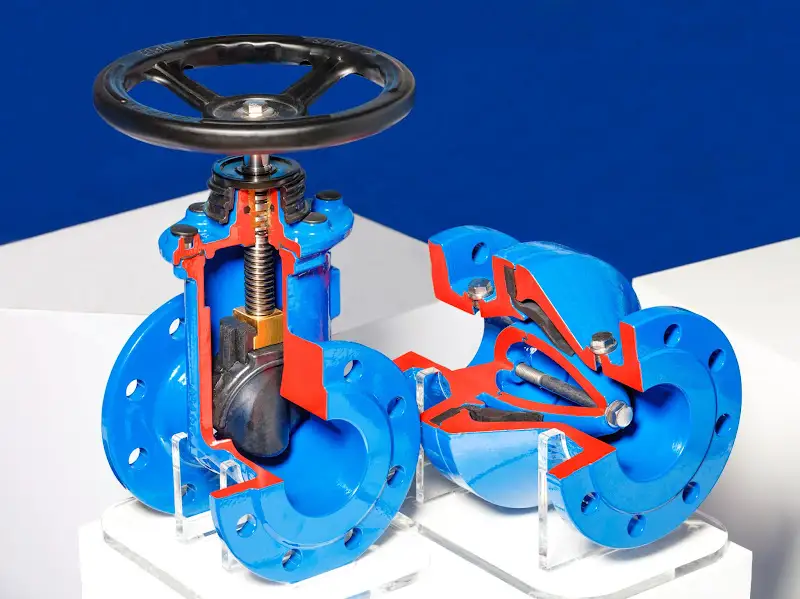

PalancaWhen it comes to parallel slide gate valve vs wedge gate valve, the main difference lies in how each type seals the flow. A parallel slide gate valve uses two parallel seats and a sliding gate to control flow, while a wedge gate valve uses a wedge-shaped disc that presses tightly between angled seats to stop the flow completely.

Both valves perform the same function — isolating flow — but they differ in design, performance, and application. Understanding these differences helps you choose the right valve for your industrial system.

Understanding Gate Valves: The Basics

Gate valves are linear-motion valves used to start or stop fluid flow. They’re widely used in pipelines for oil, gas, power, and chemical industries because they offer minimal flow resistance and full bore openings. Both the parallel slide gate valve and the wedge gate valve fall under this category, but their sealing mechanisms make them suitable for different conditions.

How Does a Parallel Slide Gate Valve Work?

A parallel slide gate valve has two flat discs (or a slab) that slide between two parallel seats. When closed, spring or line pressure pushes the discs outward to create a seal on both sides. When open, the slab aligns with the pipe bore, allowing smooth, unrestricted flow.

Key features:

- Provides low flow resistance and allows pigging (cleaning) in pipelines.

- Offers bidirectional sealing, meaning it seals effectively in both directions.

- Prevents thermal binding, making it ideal for high-temperature and fluctuating systems.

Common applications: oil and gas pipelines, refineries, and power plants.

What Are the Advantages of a Parallel Slide Gate Valve?

A parallel slide gate valve offers excellent sealing even under low pressure due to its mechanical spreading design. It’s perfect for pipelines carrying steam, gas, or particulate fluids. Since its sealing surfaces are parallel, they experience less wear, extending valve life. This design also avoids issues like jamming from temperature changes, a common problem in other types of valves.

Understanding the Wedge Gate Valve

A wedge gate valve features a disc that forms an angle — or wedge — between two inclined seats. When the valve closes, the disc is forced down, creating a tight, compression-based seal. This wedge shape helps maintain a strong seal even under high pressure.

Key features:

- Offers high sealing reliability for high-pressure systems.

- Simple and compact design suitable for most industrial applications.

- Available in solid, flexible, or split wedge types to suit different temperature and pressure needs.

However, because of its wedging action, it may face thermal binding during extreme temperature changes, requiring careful material and design selection.

Parallel Slide Gate Valve vs Wedge Gate Valve: A Direct Comparison

| Característica | Parallel Slide Gate Valve | válvula de compuerta de cuña |

| Sealing Type | Parallel surfaces with self-sealing or spring load | Wedge-shaped forced sealing |

| Thermal Binding | None | Possible at high temperatures |

| Flow Resistance | Very low | Low |

| Bidirectional Sealing | Yes | Usually unidirectional |

| Mantenimiento | Complex but durable | Easier, with fewer parts |

| Best Use | High-temperature, piggable, or thermal cycling systems | General industrial and high-pressure systems |

Choosing the Right Gate Valve for Your System

When selecting between a parallel slide gate valve and vs wedge gate valve, consider your pressure, temperature, and media type. For systems with high temperatures and fluctuating conditions, the parallel type is ideal. For standard, high-pressure applications, a wedge gate valve is often more cost-effective and durable.

Preguntas frecuentes

1. What are the advantages of a parallel slide gate valve?

It provides bidirectional sealing, low torque operation, and no thermal binding, making it ideal for steam and high-temperature services.

2. How does a parallel slide gate valve work?

It uses two parallel discs that slide open or closed, sealing through spring force or line pressure.

3. When should I use a wedge gate valve?

Use it for high-pressure systems where tight sealing and compact design are important.

4. Which valve is better for thermal cycling?

The parallel slide gate valve performs better under frequent temperature changes.

Conclusión

Understanding the difference between a parallel slide gate valve vs wedge gate valve helps you make safer, more efficient decisions for your operations. Both designs offer distinct strengths — choose based on pressure, temperature, and media.

For dependable, globally certified valves that meet API6D, ISO9001, y fire-safe standards, explore the GOWIN Industrial Valve collection. We manufacture high-quality valves engineered for precision, safety, and longevity. Visit Válvula industrial GOWIN to find the right valve for your next project.