Table of Contents

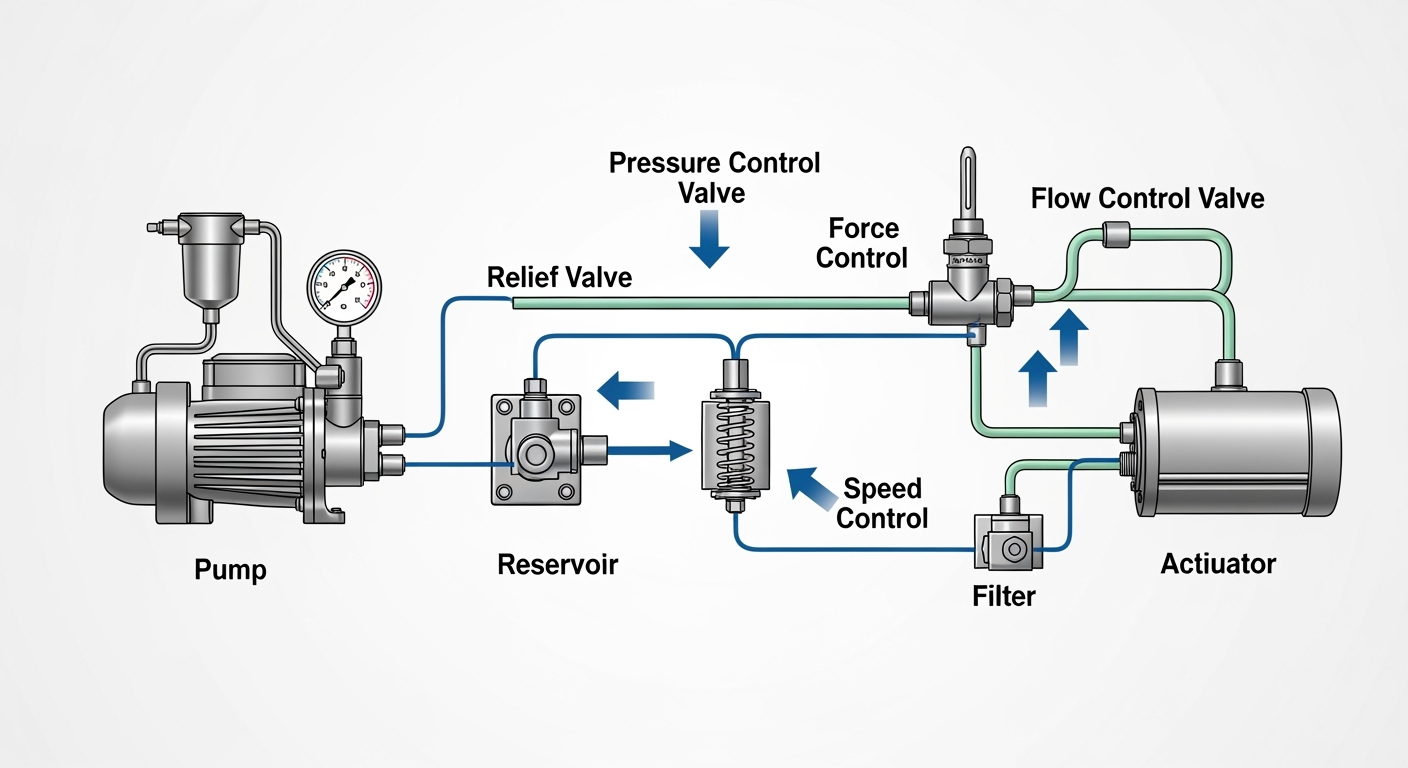

ToggleThe key difference between a pressure control valve and a flow control valve is what they regulate: pressure control valves manage force. In contrast, flow control valves manage the speed and volume of hydraulic fluid. Both are essential for maintaining safe and efficient hydraulic system performance.

Choosing the right valve impacts machine reliability, energy use, and operator control. This article explains how each valve works, its functions in hydraulic systems, and how to select the right one for your application.

The Fundamental Role: Controlling Force vs. Controlling Speed

A hydraulic pressure control valve regulates the force in a system by keeping pressure at a desired level, ensuring safety and consistent performance. It prevents overloads that could damage components. On the other hand, a hydraulic flow control valve controls the speed of actuators such as cylinders or motors by managing the fluid flow rate. Because pressure and flow are interdependent, adjusting one often affects the other, making it crucial to manage both separately for efficiency.

How Hydraulic Pressure Control Valves Work (Relief, Sequence)

The function of a pressure control valve in a hydraulic system is to protect equipment by opening or closing based on set pressure levels. Key types include:

- Relief valves: Open automatically when system pressure rises above a preset level, diverting hydraulic fluid back to the reservoir to prevent component failure and ensure safe operation of the hydraulic circuit.

- Sequence valves: Control the order of actuator operation by allowing flow to a secondary circuit only after a set pressure is reached in the primary circuit, ensuring proper timing in multi-actuator systems.

GOWIN Industrial Valve offers customized hydraulic pressure control valves for agricultural and construction machinery. As an OEM partner, GOWIN ensures international certifications (API6D, ISO9001) and provides flexible delivery and on-site technical support to equipment manufacturers and rental companies.

High-performance control valves engineered to international standards (ASME, API, JIS, BS, DIN). Available in sizes from 3/4″ to 72″ with pressure ratings up to 42.0 MPa. Suitable for water, oil, and gas applications with temperature range from -196℃ to 650℃.

Explore ProductHow Hydraulic Flow Control Valves Work (Fixed, Adjustable, Proportional)

A hydraulic flow control valve manages actuator speed by adjusting fluid volume. The types of flow control valves in hydraulic systems include:

- Fixed orifices: Basic openings that create a set restriction, keeping the fluid flow at a constant rate regardless of operator input. They are simple and reliable for consistent tasks.

- Adjustable valves: Designed with a movable component so operators can change the opening size. This manual adjustment lets users increase or decrease actuator speed as needed in the hydraulic circuit.

- Proportional control valves: Use an electronic signal to vary the opening precisely. These valves provide accurate flow control in real time, making them ideal for equipment that requires frequent speed changes or fine positioning.

In tractors and loaders, these valves are also called hydraulic speed control valves because they directly influence movement speed. GOWIN designs flow control solutions that integrate floating and power output functions, ensuring machines operate smoothly and efficiently in demanding agricultural tasks.

Can One Valve Do Both? Understanding Pressure-Compensated Flow Controls

A pressure-compensated flow control valve combines both functions. It maintains a consistent flow regardless of pressure changes, making it ideal for equipment where load variations occur frequently. However, for most applications, separate hydraulic pressure control valves and hydraulic flow control valves provide better precision and flexibility.

System Design: Where to Place Each Valve Type for Optimal Performance

In a well-designed hydraulic circuit:

- Pressure control valves are usually placed close to pumps or actuators to protect the system from overpressure.

- Flow control valves are placed in lines feeding actuators to manage speed effectively.

Correct valve placement ensures equipment safety, reduces energy waste, and extends component life. GOWIN’s engineering team assists OEMs with optimal valve placement, offering on-site guidance, installation support, and fast-response service to maximize machine reliability.

Conclusion: Choosing the Right Valve for the Job

Both hydraulic pressure control valves and hydraulic flow control valves play key roles in system safety and performance. Selecting the right valve type improves machine efficiency, reduces wear, and ensures precise operation.

GOWIN Industrial Valve offers customized, certified valve solutions for OEMs and distributors worldwide. With flexible delivery and on-site support, we help you achieve reliable, efficient hydraulic systems. For inquiries or quotes, reach out to our team here – we’re ready to help with solutions, quotes, and expert advice.

FAQs

1. What is the function of a pressure control valve in a hydraulic system?

It regulates system pressure to prevent overload, protecting components from damage.

2. What are the types of flow control valves in a hydraulic system?

They include fixed orifices, adjustable valves, and proportional control valves.

3. Can one valve control both pressure and flow?

Yes, a pressure-compensated flow control valve can maintain consistent flow despite pressure changes.4. Where should a pressure control valve be placed?

It is usually installed near the pump or actuator to prevent overpressure.