Table of Contents

ToggleUnderstanding Pneumatic Directional Control Valves for System Design

Pneumatic directional control valves are the heart of many automation and process control systems. These valves manage the path of compressed air to actuators, cylinders, or other devices, allowing machines to perform precise actions. They include options such as a 3-way pneumatic control valve, a pneumatic 5/2 directional control valve, and a 5/3 pneumatic directional control valve. By understanding these valve types and their spool designs, engineers and technicians can design systems that are efficient, reliable, and easy to maintain.

This guide explains how these valves work, what the numbers mean, and how to select the right valve for your needs.

What is a Directional Control Valve and Its Function?

A pneumatic directional control valve directs compressed air to specific points in a system, controlling actuator motion. It consists of ports, a spool pneumatic directional control valve mechanism, and an actuator such as a solenoid or pilot. These valves are vital for tasks like clamping, pressing, or moving loads in manufacturing, automotive, and robotics applications.

Key Takeaways:

- It controls airflow direction and actuator movement.

- It can be operated manually, pneumatically, or electrically.

- It is essential for automation and process efficiency.

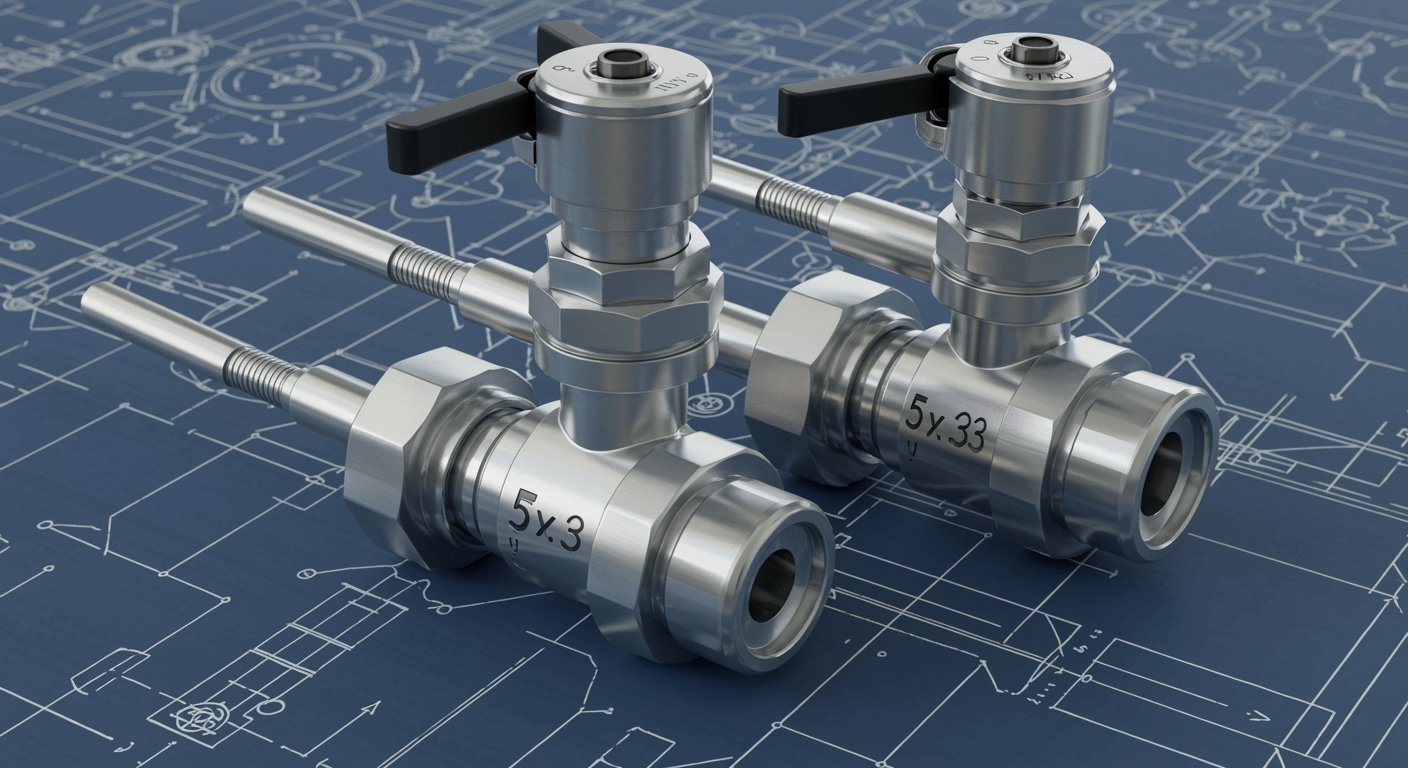

High-performance control valves engineered to international standards (ASME, API, JIS, BS, DIN). Available in sizes from 3/4″ to 72″ with pressure ratings up to 42.0 MPa. Suitable for water, oil, and gas applications with temperature range from -196℃ to 650℃.

Explore ProductExplaining the Numbers: What Do 3/2, 5/2, and 5/3 Mean?

The numbers in a pneumatic directional control valve refer to its ports and positions. The first number is the number of ports; the second is the number of positions.

- 3/2 valve: Three ports, two positions. Often used for single-acting cylinders and as a compact 3-way pneumatic control valve.

- 5/2 valve: Five ports, two positions. Common for double-acting cylinders as a pneumatic 5/2 directional control valve.

- 5/3 valve: Five ports, three positions. Offers a center position for specific functions like pressure release or blocking, and is often called a 5/3 pneumatic directional control valve.

A Deep Dive into 3/2 Way Valves: Applications and Symbols

A 3/2-way pneumatic directional control valve has one inlet, one outlet, and one exhaust port. It can be normally open (NO) or normally closed (NC). These valves are common in single-acting cylinders where air extends the piston, and a spring retracts it.

Applications:

- Single-acting cylinder control – provides air to extend the piston while a spring returns it when vented.

- Vacuum and pressure release functions – used to create suction or safely discharge air from a system.

- Blow-off applications – clear debris or excess material from work surfaces using controlled bursts of compressed air.

Symbols: Pneumatic diagrams use simple symbols showing ports and flow direction, helping designers plan circuits clearly.

A Deep Dive into 5/2 Way Valves: The Workhorse of Pneumatics

The 5/2 valve is widely used for double-acting cylinders. It has two working ports for extending and retracting an actuator. These valves can be solenoid-operated, pilot-operated, or both.

Why it’s popular:

- Easy to integrate with most pneumatic directional control valve setups

- Provides fast, repeatable switching between two flow paths for double-acting cylinders

- Supports both solenoid and pilot operation, making it suitable for industrial automation lines, packaging machines, and robotic arms where continuous forward and reverse motion is required

A Deep Dive into 5/3 Way Valves: Center Position Functions Explained

A 5/3 pneumatic directional control valve has five ports and three positions. The center position defines how the actuator behaves when the valve is not actuated:

- Closed center: All ports are blocked, so the actuator stays locked in place, and pressure is trapped in the chambers.

- Open center: All ports are vented to exhaust, releasing pressure and allowing the actuator to move freely to a neutral position.

- Pressure center: Both actuator ports receive pressure, holding the actuator mid-stroke with equal force on each side.

This valve type is ideal for applications that need precise mid-stroke holding, safe pressure release, or controlled stopping during machine operations.

How to Select the Right Valve for Your Pneumatic Circuit

Selecting the right pneumatic directional control valve requires knowing your actuator type, pressure, flow needs, and control method. Consider the environment, required certifications, and system reliability.

GOWIN Industrial Valve Advantage:

- Provides custom valve design and production for industries like petrochemicals, mining, and power generation.

- Offers drawing support to meet unique project requirements.

- Valves have an extremely low problem rate, ensuring stable, long-term use.

- The technical team is well-versed in international standards such as API and ISO, ensuring global compliance.

If your system needs a control valve with a pneumatic actuator or specific features like a pneumatic control valve positioner, GOWIN can design a solution that matches your exact working conditions.

FAQ

What does a pneumatic directional control valve do?

It directs compressed air to control the movement of actuators in a pneumatic system.

What is a 3/2-way valve used for?

It is commonly used for single-acting cylinders, blow-off, and vacuum applications.

How to calibrate a pneumatic control valve?

Calibration involves adjusting the valve and actuator so they respond accurately to control signals. This is done using a pneumatic control valve positioner.

Why choose GOWIN valves?

They are durable, meet international standards, and can be customized for unique industrial needs.

Conclusion

After understanding how each type of pneumatic directional control valve functions, the final step is choosing a solution that aligns with your system needs. GOWIN Industrial Valve combines technical expertise, global certifications, and strong customization capabilities to deliver solutions that match complex industrial requirements. Whether you need a standard 3/2 valve, a 3 way pneumatic control valve, or a custom 5 3 pneumatic directional control valve, GOWIN ensures reliable, compliant, and long-lasting performance for your systems. Contact our team today to get expert support and a customized quote for your next project.